Double layer mezzanine platform project

GDPilot Racking provide you with the highest quality storage space and meet your request.

Mezzanine platform, also known as a work platform, is suitable for situations where the site is limited and there are a wide variety and a small quantity. It can increase the utilization rate of the existing site several times and can be used in conjunction with the operation of suitable elevators.

Mezzanien platforms can usually be designed with 2-3 floors, and the separated space can be used for storage or office purposes. Customized according to warehouse area, height, and cargo size, it can avoid beams and columns. Stairs and cargo elevators are set up, and the tally platform can also be reserved, so that the Cart can be reasonably connected with the cargo elevator to make full use of space.

This type of platform is suitable for large and medium-sized warehouses with high warehouses, where there are multiple types of large batches or small batches of goods, manual storage, and large inventory. Small footprint and high space utilization.

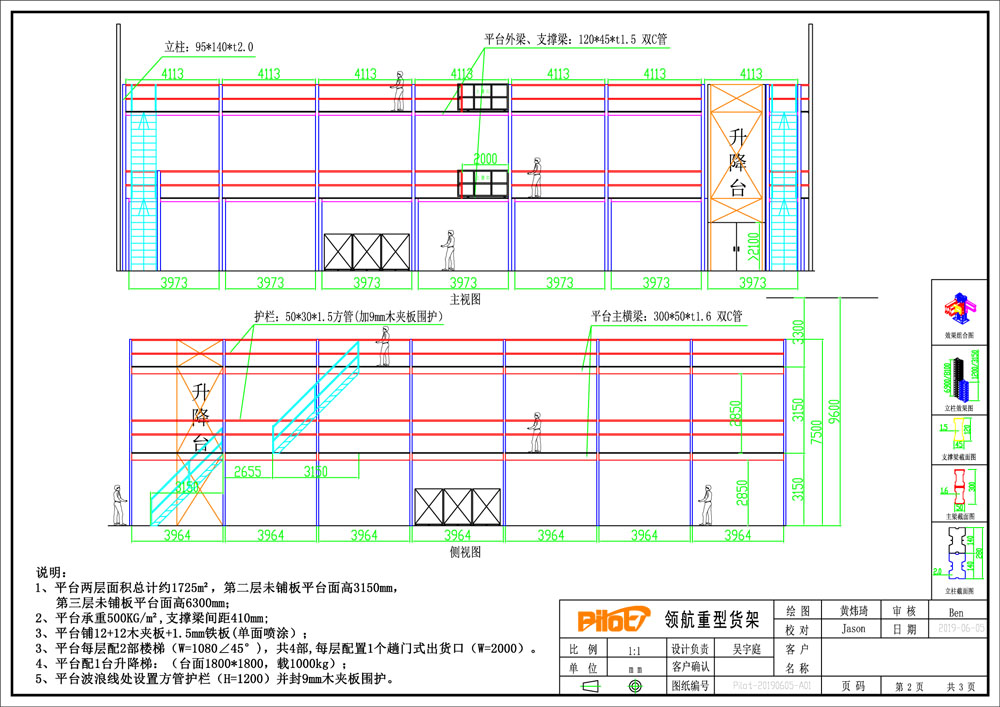

The double layer steel platform project completed by GDPilot Racking is a well-known large enterprise. According to customer needs, the design and planning of the steel platform is about 1000 square meters per floor, with a capacity of 500kg per square meter and a height of 7.5 meters. Of course, while considering customer needs, GDPilot Racking also fully considers safety issues. After detailed discussion and calculation, it also ensures the safety of the steel platform in the later stage of use.

GDPilot Racking provides professional logistics designers with free on-site design services. We will design warehouse shelves from a safe, reasonable, and economical perspective based on customers' actual needs. GDPilot Racking has always been focused on the design and manufacturing of attic shelves, attic platforms, and heavy-duty shelves. Currently, we wholeheartedly serve tens of thousands of enterprises to improve the operational and management efficiency of storage sites, thereby bringing better benefits. The products are mainly made of thickened hot rolled steel, which is 30% more than the materials used in the same industry. The advanced production line and a batch of automatic beam welding production equipment are strictly in accordance with the Shelf Industry Standard. The shelves produced have 12 folds, high Factor of safety and large bearing capacity, 1.65 times of the traditional shelves. Since its establishment for fifteen years, GDPilot Racking not only has more than 10 automated heavy-duty shelving production lines, but also has introduced high-end heavy-duty shelving production equipment such as double pulse automatic welding, foreign cold bending forming, CNC punching, and electrostatic spray molding, which can meet the needs of different customers for customized production.